Are you familiar with seal metal? It’s a fantastic kind of metal that is appearing more and more. It is being increasingly adopted across various industries. But what is , exactly? Believe it or not, since the purpose of a seal metal is for holding torque in high temperature and pressure it is incredibly true and tough material. It is formed by fusing various metals using a unique process. It is this special way of combining metals that actually makes seal metal even stronger than if it was made from one type of metal.

Seal metal has something really awesome about it which is that it does not rust. Rust is what happens when metal gets wet and begins to decay. Seal metal doesn’t rust, so it can remain strong and last for a long time. This is Makes it suitable for different fields where it has to be quite solid and reliable for long time.

XingHui Seal is a professional, one-stop manufacturer for seal metal parts, widely used in cover projects. They collaborate with their clients to design custom components that are perfect for each and every task. That way, they can build some very unique and useful things that perfectly fit into what is needed.

The first step in this process is to design the parts. The people of XingHui Seal has a special computer program grouped by licensed engineers to make 3d pictures of the type of pieces they are going to make. These 3D models tell us exactly how the components will look and fit together. Afterward, they use machines to slice and shape the metal so that it exactly fits the design. We call this process CNC machining, or computer numerical control machining.

After the parts are created, they are rigorously tested to make sure they are sturdy enough for their intended application. The testing examines the performance of parts at various temperatures and pressures. XingHui Seal places their high standard first and foremost, ensuring that what they create isn't just strong, but reliable as well. Each component is subjected to multiple tests in order to ensure that they meet their high quality standards.

You may not know it, but seal metal surrounds us in daily life. It is used to make all manner of things, from cooking pots and pans to electronics and vehicles, including cars. A major advantage of seal metal is that it can function appropriately in very hot areas, for example, auto motors. These engines run very hot and must hold very high pressure — that’s where seal metal really performs.”

Another branch where seal metal can be highly relevant is aerospace, military, etc. Strengths in these fields are critical. Seal metal is made into components for jets, missiles and other high-performance machines. So, seal metal is there protecting us in many ways when flying in an airplane or using sophisticated technology.

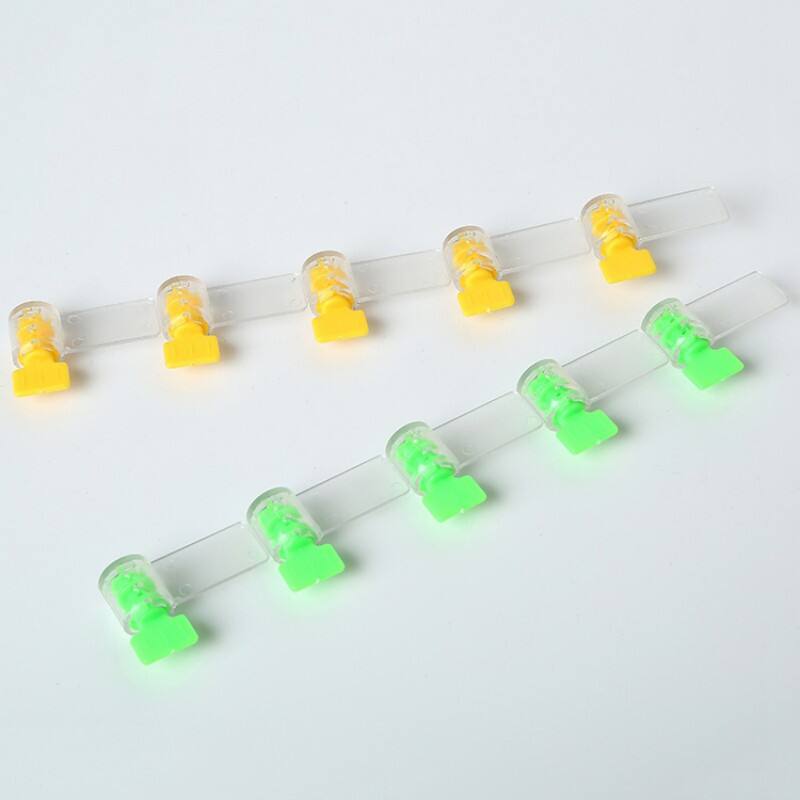

XingHui has carefully developed five series of seal products, including wire seals, high-security seals, meter seals, plastic seals and RFID seals. These series not only cover a wide range of product models, but each series has been carefully designed to meet the security needs of different industries and scenarios.

We are committed to providing excellent after-sales service. Before customers place an order, we will conduct sample confirmation. Once the order is completed, customers can choose to come to the company for personal inspection before we ship it; or, we will take photos and videos of the completed order for customers to confirm. Each order will go through a complete order tracking process. In addition, we have carefully selected high-quality logistics export services for our customers

XingHui's product line has more than 100 models, which enables the company to provide customers with precise customization services, ensuring that every customer can find a seal product that meets their specific purchasing needs. Whether it is used for logistics transportation, equipment safety, instrument calibration or intelligent identification, XingHui's seal products can provide reliable security.

The company has been certified by the internationally recognized ISO 9001 standard and the world-renowned SGS company. These certifications demonstrate the company's commitment to quality management and continuous improvement, ensuring that the high standards set by these organizations are met. The process of obtaining these certifications involves demonstrating a strong quality management system that covers aspects such as customer satisfaction, process control and continuous improvement. By following these standards, the company demonstrates its commitment to excellence and gains a competitive advantage in the market.