Gdy ludzie wydają czas i pieniądze na niestandardowy pieczęć, chcą, aby był estetyczny i trwały. Drukowanie i znakowanie laserowe to dwie główne metody nanoszenia wzoru lub liter na pieczęć. Drukowanie polega na naniesieniu farby lub farby na powierzchnię pieczątki; znakowanie laserowe to użycie lasera do zmiany samej powierzchni. W XingHui Seal z doświadczenia wiemy, że znakowanie laserowe jest lepsze od drukowania pod wieloma względami. Sprawia, że pieczęć jest mocniejsza, wyraźniejsza i bardziej odpowiednia do różnych potrzeb. W tym artykule omawiamy, dlaczego znakowanie laserowe jest lepsze niż drukowanie, szczególnie jeśli potrzebujesz pieczątki, która nie będzie się łamać ani wypływać oraz jeśli ma być wykonana w dużych ilościach

Dlaczego znakowanie laserowe jest lepsze niż drukowanie w przypadku trwałej niestandardowej pieczątki

Wydaje się tak proste i szybkie wydrukowanie projektu na niestandardowym stemplu, ale często nie upływa wiele czasu, zanim odcisk zaczyna znikać. Tusz lub farba znajduje się na powierzchni stempla, a z czasem może się zadzierać, odpryskiwać lub łuszczyć, szczególnie jeśli stempel jest często używany lub obsługiwany niedbale. Na przykład, jeśli wielokrotnie używasz stempla na dokumentach, wydrukowany obraz może stopniowo wypłowiać, aż do punktu, w którym widoczny będzie jedynie jego odcisk. Dzieje się tak, ponieważ drukowanie polega na stosowaniu materiałów, które znajdują się na powierzchni i nie są częścią samego stempla. W przeciwieństwie do tego, znakowanie laserowe zmienia powierzchnię obiektu, pozostawiając ślad poprzez wypalenie lub przekształcenie małych obszarów materiału w określone wzory. Zapewnia to, że projekt staje się integralną częścią stempla i nie może zostać po prostu zetrty. Niezależnie od tego, czy poddasz stempel trudnym warunkom, czy wyczyścisz go środkami chemicznymi, znak laserowy pozostaje wyraźny i ostry. W XingHui Seal przetestowaliśmy obie metody na wielu stemplach i zauważyliśmy, że stempel z oznakowaniem laserowym uszczelnienia trwają znacznie dłużej i zachowują swoje detale. Jest to kluczowe dla firm lub osób indywidualnych, które wymagają bezpiecznego pieczątkowania dokumentów żeglugowych, produktów i wielu innych. Druk może na początku wyglądać ładnie, ale oznakowanie laserowe świetnie się sprawdza w czasie i nie traci jakości. Ponadto druki promocyjne nie oferują takiej szczegółowości jak znak laserowy. Ma to za efekt nadanie pieczęci bardziej profesjonalny wygląd, co oznacza również, że jest ona trudniejsza do sfałszowania, zwiększając tym samym bezpieczeństwo. Drukowane pieczątki czasem rozmazują się lub kolor nie jest jednolity, natomiast znaki laserowe są zawsze czyste i spójne. Jeśli szukasz trwałości oraz estetycznych pieczęci, to oznakowanie laserowe jest najlepszym wyborem

Dlaczego oznakowanie laserowe jest idealne dla dużych partii niestandardowych pieczęci

Gdy firma potrzebuje dużej liczby niestandardowych pieczęci, szybkość i koszt są bardzo ważne. Drukowanie jednej pieczęci naraz może być bardziej czasochłonne, ponieważ atrament musi wyschnąć, a ponadto może dojść do błędów, jeśli atrament się rozmazuje lub kolory zostaną pomieszane. Może to opóźnić cały proces i prowadzić do marnowania materiałów. Znakowanie laserowe działa inaczej. Dzięki maszynie laserowej można oznaczać pieczęć po pieczęci bardzo szybko, a wynik jest całkowicie suchy — nie trzeba na nic czekać. Oznacza to, że produkcja może przebiegać szybciej i sprawniej. Firma XingHui Seal ma również doświadczenie w zakresie maszyn do znakowania laserowego, ponieważ potrafią one skuteczniej radzić sobie z dużymi zamówieniami, ponieważ projekt jest zaprogramowany w urządzeniu, a każda pieczęć jest identyczna. Nie ma ryzyka pomyłek kolorystycznych ani rozmazanych śladów, stwierdzono, a także mniejsza konieczność przeprowadzania kontroli jakości po zakończeniu produkcji. A ponieważ znakowanie laserowe nie polega na użyciu atramentu czy chemikaliów, oznacza to również mniejsze wydatki na materiały i czyszczenie. Jest to również nieco lepsze dla środowiska, co jest miłe. Po drugie, znakowanie laserowe jest bardzo wszechstronne. Jeśli klient chce zmodyfikować projekt lub dodać numery lub litery do każdej pieczęci, wszystko to można łatwo zrobić, modyfikując program w maszynie laserowej. Gdyby miało to być nadrukowane, oznaczałoby to konieczność wykonania nowych sit lub form oraz większe wydatki, więcej czasu itp. W przypadku dużych projektów znakowanie laserowe jest oczywiście bardziej rozumnym wyborem. Oszczędza czas, zmniejsza liczbę błędów i pomaga obniżyć koszty. Po trzecie, XingHui Seal stosuje znakowanie laserowe, aby złagodzić problem klientów związany z uzyskaniem wysokiej jakości pieczęci w dużych ilościach. W ten sposób firmy mogą mieć pewność, że otrzymają dokładnie to, co zamówiły, a pieczęcie będą gotowe do szybkiego użycia. Gdy produkuje się dużą liczbę pieczęci, niezawodność i szybkość odgrywają ogromną rolę, a znakowanie laserowe oferuje oba te atuty.

Jak znakowanie laserowe rozwiązuje typowe problemy z drukowanymi pieczęciami na zamówienie

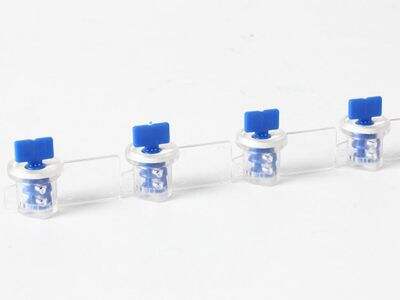

Gdy potrzebujesz pieczątki na zamówienie do użytku w firmie lub na potrzeby prywatne, sama pieczątka powinna być czytelna i trwała. Wiele osób uważa, że drukowanie to sensowny sposób wykonywania tego typu pieczęci, jednak istnieją pewne wady drukowanych pieczęci, które znakowanie laserowe potrafi łatwo wyeliminować. W XingHui Seal oferujemy możliwość stosowania znakowania laserowego, ponieważ jest ono znacznie lepsze niż tradycyjny druk. Jedną z wad drukowanych pieczęci jest to, że z czasem atrament może się zetrzeć lub wypłowić. Może to skutkować nieestetycznym wyglądem pieczątki lub trudno czytelnym odciskiem. Drukowane odciski mogą również rozmazać się, jeśli zmokną lub często się nimi posługujesz. Znakowanie laserowe natomiast polega na wypaleniu wzoru bezpośrednio w materiale pieczątki. Powstaje w ten sposób trwały, odporny na wypłowywanie odcisk, który trudno jest usunąć. Nie wypłynie, nie rozmazie się, niezależnie od tego, jak intensywnie używa się pieczątki lub gdzie jest przechowywana. Kolejną wadą drukowanych uszczelnienia polega na tym, że atrament może źle przylegać do różnych rodzajów materiałów, co może powodować nierówny lub ubrudzony wygląd stempla. Znakowanie laserowe można stosować z wieloma materiałami, w tym metalem, plastikiem i skórą, zapewniając za każdym razem czysty i gładki wzór. Gwarantuje to, że Twój znak laserowy będzie wyraźny i trwały, niezależnie od wybranego przez Ciebie wykończenia materiału Twojego niestandardowego stempla. Druki stempli zazwyczaj mają ograniczoną możliwość przedstawienia szczegółowego projektu. Drobne litery lub cienkie linie mogą nie wyjść wyraźnie i wyglądać rozmazane. Znaki laserowe łatwo tworzą szczegółowe projekty oraz bardzo małe napisy. To zapewni, że Twój stempel będzie wyglądał dokładnie tak, jak chcesz, bez rozmytych fragmentów czy brakujących detali. W każdym razie, grawerowanie laserowe rozwiązuje wiele dużych problemów, które stwarza drukowanie niestandardowych stempli. XingHui Seal uważa, że znakowanie laserowe ma sens dla naszych klientów, ponieważ stemple są bardziej trwałe, lepiej wyglądają i mogą być stosowane w różnorodnych zastosowaniach

Gdzie laser wyznacza idealne niestandardowe uszczelnienie i markę żywności, zapewniając precyzję w spójności marki

Tworząc niestandardowy znak, ostatnią rzeczą, której chcesz, jest coś przypadkowego. Dotyczy to w szczególności sytuacji, gdy używasz znaku do prezentowania swojej marki. Jeśli znak nie jest nigdy taki sam, może to wprowadzać zamieszanie wśród klientów i sprawiać, że Twoja marka będzie wyglądać mniej profesjonalnie. Znakowanie laserowe to doskonały sposób na zapewnienie precyzji i spójności w produkcji niestandardowych znaków. W XingHui Seal wykorzystujemy technologię znakowania laserowego, dzięki której nie występują błędy, a dokładnie ten sam projekt może być odtwarzany na każdym produkowanym znaku. Znakowanie laserowe jest precyzyjne, ponieważ wiązka laserowa jest kontrolowana przez komputer. Oznacza to, że projekt jest dokładnie kopiowany z obrazu cyfrowego, bez udziału ludzkiego błędu. Drukowane znaki mogą czasem zawierać drobne niedoskonałości, ponieważ atrament może się rozmywać lub maszyna drukująca nie działa w stu procentach dokładnie. Dzięki znakowaniu laserowemu projekt jest wyraźny i czysty, idealnie oddający wszystkie drobne detale. Jest to szczególnie ważne, jeśli Twój znak zawiera logo lub tekst, które muszą być czytelne. Pewność, że każdy znak będzie miał dokładnie ten sam kolor i odcień, to kolejny sposób, w jaki znakowanie laserowe wspomaga spójność marki. Drukowane znaki mogą występować w różnych odcieniach, w zależności od użytego atramentu lub procesu drukowania, natomiast te wykonane metodą laserową mają zawsze identyczny odcień, ponieważ uzyskuje się go poprzez zmianę koloru powierzchni znaku, a nie poprzez stosowanie atramentu. Oznacza to, że niezależnie od tego, czy zamawiasz 10, czy 1000 znaków od XingHui Seal, wszystkie będą miały identyczny, idealny wygląd. Znakowanie laserowe pozwala również na tworzenie bardzo skomplikowanych i szczegółowych projektów, które oddają unikalny charakter Twojej marki. Małe logotypy, cienkie linie czy specjalne czcionki – wszystko jest możliwe, bez ryzyka utraty czytelności projektu. To właśnie sprawia, że Twoja marka wyróżnia się i wygląda profesjonalnie. Podsumowując, znakowanie laserowe służy poprawie dokładności i jednolitości niestandardowych znaków, co ma duże znaczenie dla utrzymania jasnego wizerunku marki. W XingHui Seal zapewniamy, że wszystkie znaki są produkowane zgodnie z surowymi standardami jakości, aby Twoja marka mogła prezentować się najlepiej

Sposób, w jaki znakowanie laserowe obniża koszty i zwiększa efektywność w hurtowej sprzedaży uszczelek na zamówienie

Podczas zakupu uszczelek niestandardowych w dużych ilościach najważniejsze są koszt i szybkość. Nikt nie chce czekać zbyt długo ani płacić zbyt wiele za uszczelki, które mogą się nie wytrzymałe. Te problemy można rozwiązać dzięki znakowaniu laserowemu, które czyni proces tańszym i szybszym. Znakowanie laserowe redukuje ilość dodatkowych materiałów, które trzeba by kupić. Jednym ze sposobów, w jaki znakowanie laserowe przyczynia się do oszczędności, jest ograniczenie dodatkowych materiałów, które mogą być potrzebne. Drukowanie niestandardowych uszczelek wiązało się zwykle z użyciem tuszu, specjalnych papierów oraz innych powłok chroniących przed rozmazaniem lub zmyciem wzoru. Te elementy mogą podnosić koszty i wydłużać czas realizacji. Znakowanie laserowe nie wymaga tuszu ani dodatkowych materiałów, ponieważ spala projekt bezpośrednio w uszczelka powierzchni. To prowadzi do mniejszego zużycia materiału, co przekłada się na niższą cenę. Innym sposobem obniżenia kosztów, jaki daje znakowanie laserowe, jest redukcja błędów i marnowania. Rzeczywiste stemple mogą być nadrukowane niepoprawnie, np. z rozmazaniem lub niepełnym odciskiem. Znakowanie laserowe jest niezwykle precyzyjne i kontrolowane przez komputery, więc błędy występują znacznie rzadziej. Oznacza to mniej odpadów oraz niższe koszty naprawczych działań, które w przeciwnym wypadku kumulowałyby się. Znakowanie laserowe poprawia cały proces, zapewniając większą szybkość. Ponieważ maszyna laserowa potrafi tworzyć wzory bardzo szybko i dokładnie, produkcja każdego pieczęci trwa krócej niż przy druku. W XingHui Seal pozwala nam to realizować duże zamówienia szybciej i dostarczać Twoje stemple na czas. Szybsza produkcja oznacza, że wcześniej możesz korzystać ze swoich własnych niestandardowych stempli. Na koniec, maszyny do znakowania laserowego można przygotować do pracy z różnorodnymi projektami. Oznacza to, że jeśli chcesz zamówić wiele różnych niestandardowych stempli, laser może przełączać się między projektami niemal natychmiastowo, bez uciążliwej wymiany delikatnych form drukujących czy farb. Ta elastyczność pozwala szybciej i taniej produkować różne stemple w jednym zamówieniu. Znakowanie laserowe ma pomóc Ci zaoszczędzić pieniądze i szybciej otrzymać niestandardowe stemple hurtowo. XingHui Seal wykorzystuje tę technologię, by zapewnić Ci wysokiej jakości stemple w krótkim czasie i atrakcyjnych cenach. Dlatego znakowanie laserowe pozostaje rozumnym wyborem dla wszystkich, którzy potrzebują wielu niestandardowych stempli

Spis treści

- Dlaczego znakowanie laserowe jest lepsze niż drukowanie w przypadku trwałej niestandardowej pieczątki

- Dlaczego oznakowanie laserowe jest idealne dla dużych partii niestandardowych pieczęci

- Jak znakowanie laserowe rozwiązuje typowe problemy z drukowanymi pieczęciami na zamówienie

- Gdzie laser wyznacza idealne niestandardowe uszczelnienie i markę żywności, zapewniając precyzję w spójności marki

- Sposób, w jaki znakowanie laserowe obniża koszty i zwiększa efektywność w hurtowej sprzedaży uszczelek na zamówienie